Safety is a matter of priority and attention especially in the use and maintenance of cutting and sharpening stones. Incorrectly used wheels may cause dangerous consequences. The warnings and precautions specified in the relevant standards and the User Manual must be strictly observed when using cutting and sharpening wheels. Standards are extremely important for safety. These include the speed of product use, machine and equipment safety protection, flange mounting procedures, preventive rules during operation, storage and pre-inspection before use and finally general machine warnings.

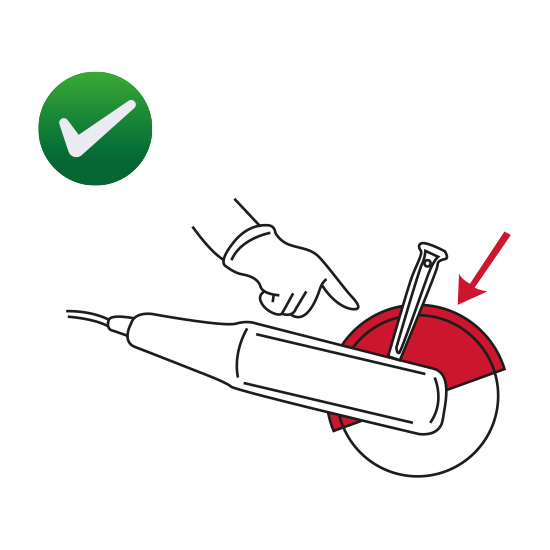

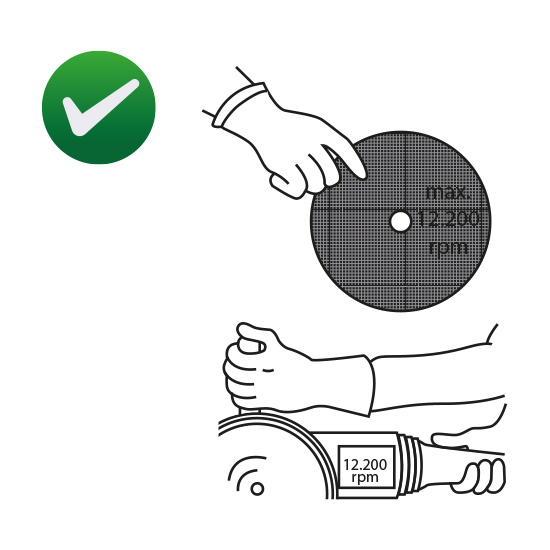

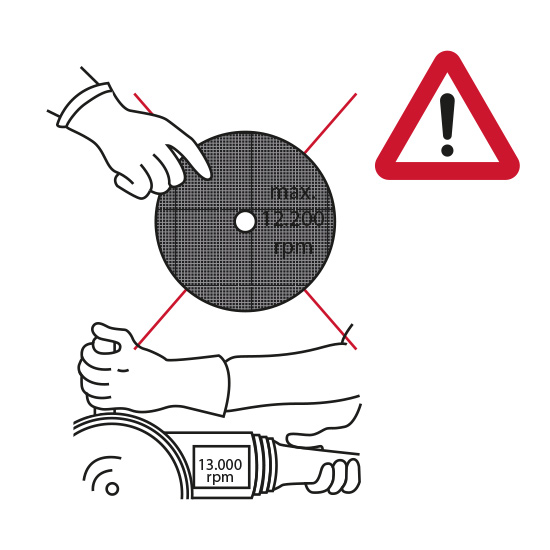

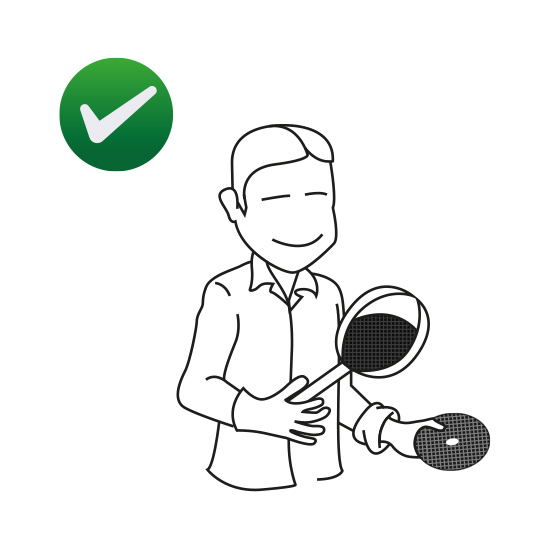

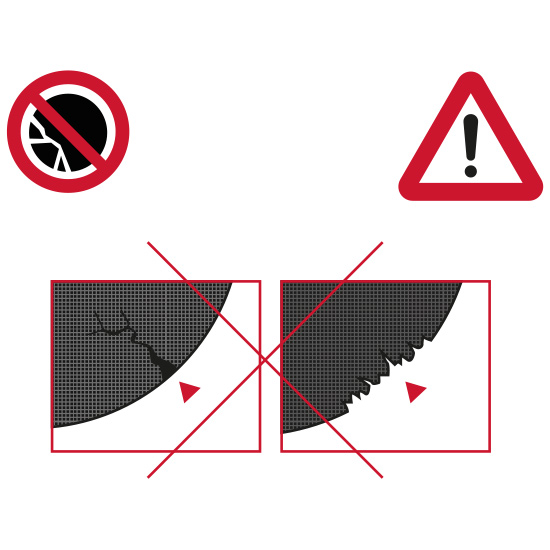

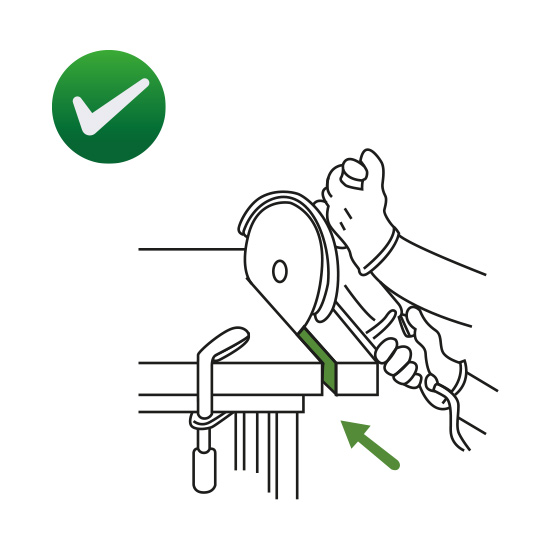

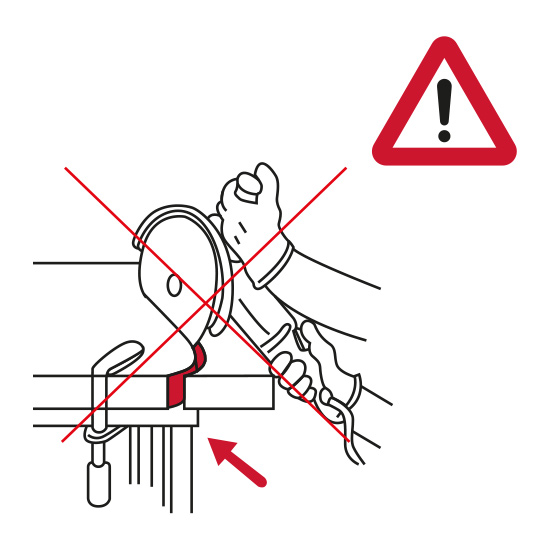

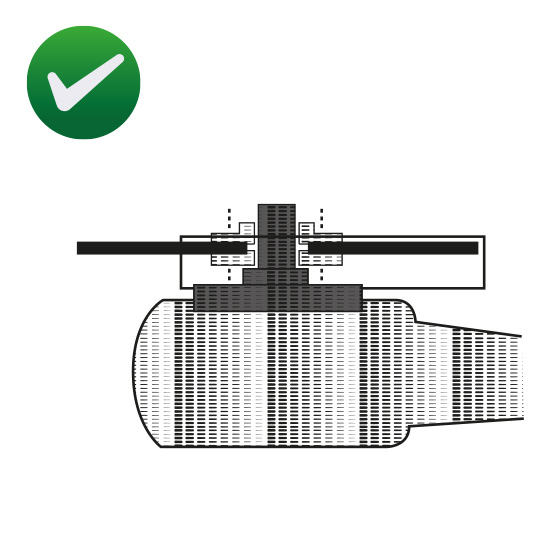

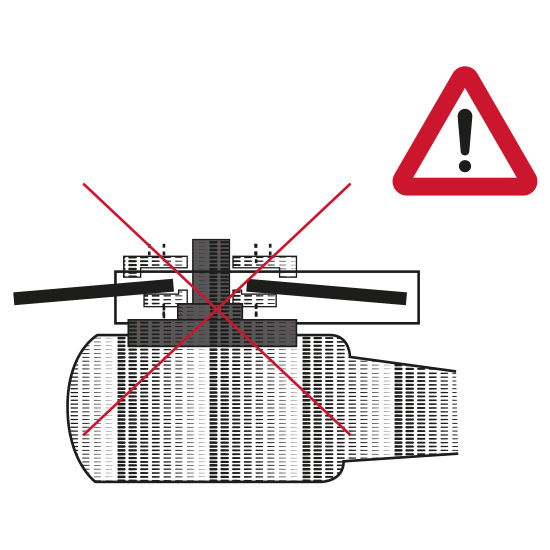

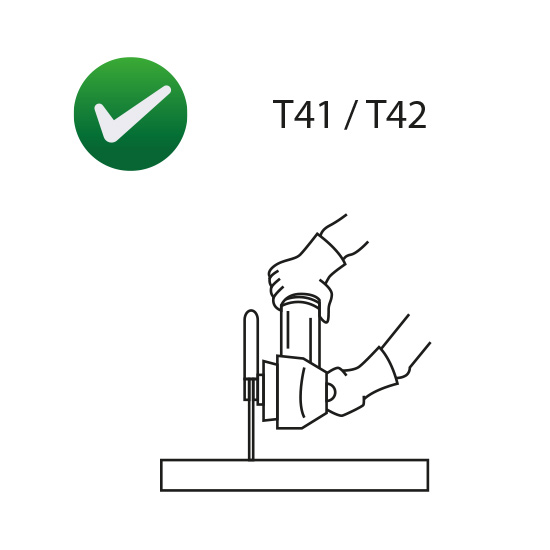

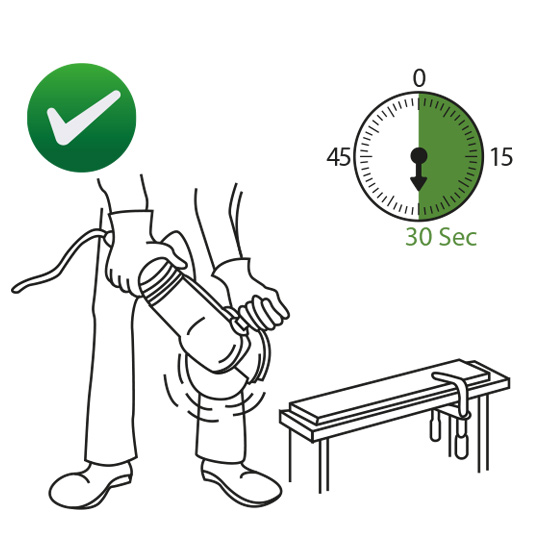

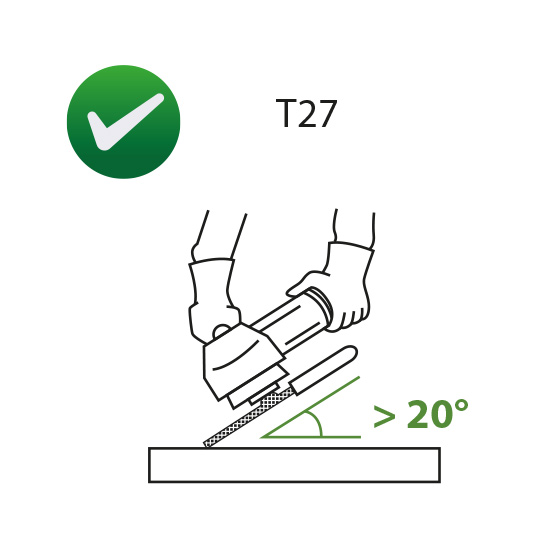

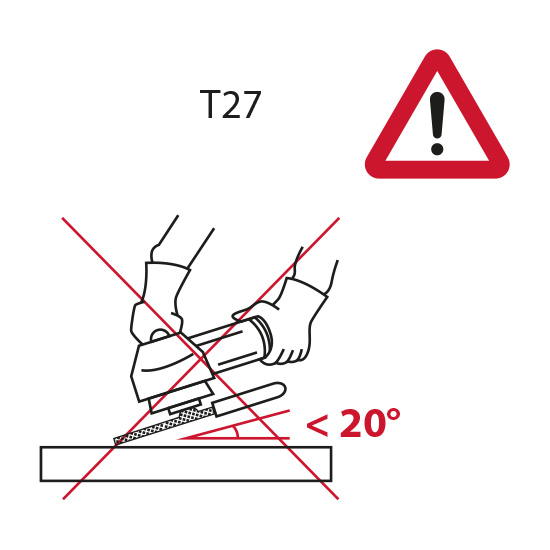

Always use cutting and grinding wheels with care and store them according to the instructions. Visually check all wheels before assembly and do not use broken or damaged products. Ensure that the machine speed does not exceed the maximum operating speed indicated on the wheel or its packaging. Check that the mounting flanges are of equal size, pressed with the required force and of the correct diameter (the diameter must be at least one third of the stone). Make sure that the workpiece is firmly supported and rests on the ground. Make sure that the workpiece is secured in place. Never remove the housings of the grinding motors. Before cutting or grinding, run the wheels for one minute at normal operating speed with the safety devices fitted. Always wear eye protection or safety equipment when cutting and grinding. Strictly follow the storage instructions. Do not use dropped, damaged or defectively manufactured wheels. Do not force the wheel into the machine or change the size of the mounting hole; if the wheel does not fit the machine, use a suitable wheel. Never exceed the maximum working speed of the stone. Do not use the mounting flanges on unclean, uneven or burr-free surfaces. Do not overtighten the mounting screws. Do not grind with cutting wheels. Do not stand directly in front of a stone that has started cutting or grinding. Do not start cutting or grinding without proper ventilation and personal protective equipment. Do not use stones for cutting and grinding which are not designed for suitable materials. Do not touch the inner part of the wheel. Never rotate, twist or tilt the cutting wheel during cutting. Do not cut or grind on a machine that vibrates excessively. Keep stones away from damp and wet environments and do not store stones. Resinous products have a shelf life of 3 years after production.FOLLOW THE RULES AND INSTRUCTIONS FOR YOUR SAFETY